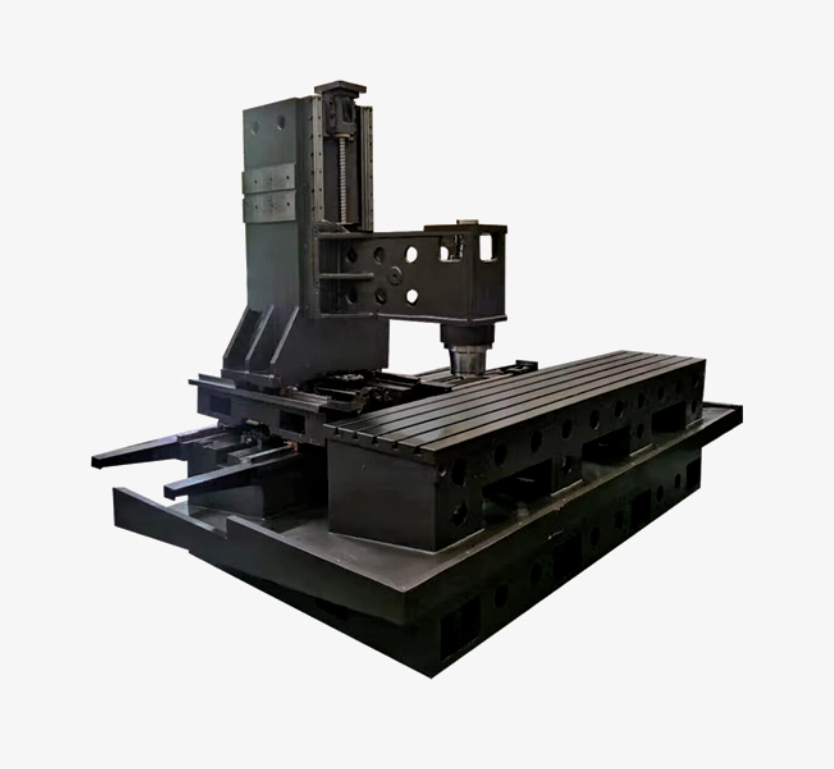

This series of drilling, tapping, milling as one of the bar vertical machining center.

High and low speed gear box, large type parts, can meet the needs of heavy processing.

Anti-splash sheet metal protection design, safe, reliable, environmental protection.

Perfect protection alarm reminding design to ensure long-term stable and reliable operation of equipment.

Compound chip removal with double twisted dragon and chain row, efficient, convenient and clean.

Widely used in: engineering machinery, rail transit, aerospace and other mechanical processing fields.

| Machine data | Unit | GDT-XC20 | GDT-XC25 | GDT-XC30 | GDT-XC35 | GDT-XC40 | GDT-XC45 | GDT-XC80 |

| Table size (L × W) | mm | 2620×550 | 3100×550 | 3870×550 | 4160×550 | 4930×550 | 5430×550 | 8782×550 |

| Maximum load of workbench | kg | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| T-slot (Number of slots - slot width × pitch) | mm | 5-18×100 | 5-18×100 | 5-18×100 | 5-18×100 | 5-18×100 | 5-18×100 | 5-18×100 |

| Table left and right travel (X-axis) | mm | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 8000 |

| Column travel (Y-axis) | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Headstock up and down travel (Z-axis) | mm | 750 | 750 | 750 | 750 | 750 | 750 | 750 |

| Distance from spindle end face to work surface | mm | 150~900 | 150~900 | 150~900 | 150~900 | 150~900 | 150~900 | 150~900 |

| Spindle form | / | Direct connection | ||||||

| Maximum spindle speed | rpm | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

| Taper of main shaft hole | / | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 |

| Spindle outside diameter | mm | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 |

| Fast moving speed (X/Y/Z) | m/min | 32/32/32 | 32/32/32 | 32/32/32 | 32/32/32 | 32/32/32 | 32/32/32 | 32/32/32 |

| Cutting feed speed | m/min | 1~10 | 1~10 | 1~10 | 1~10 | 1~10 | 1~10 | 1~10 |

| Spindle motor power | kW | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 |

| Feed motor torque (X/Y/Z) | N.m | 30/30/30(Contracting brake) | ||||||

| Cooling pump motor | kW | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Positioning accuracy | mm | ±0.012/300 | ±0.012/300 | ±0.015/300 | ±0.015/300 | ±0.015/300 | ±0.015/300 | ±0.015/300 |

| Repeated positioning accuracy | mm | ±0.008/300 | ±0.008/300 | ±0.008/300 | ±0.008/300 | ±0.008/300 | ±0.008/300 | ±0.008/300 |

| CNC system | / | FANUC | FANUC | FANUC | FANUC | FANUC | FANUC | FANUC |

| Power supply | KVA | ≥ 25 | ≥ 30 | ≥ 35 | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 40 |

| Air demand | kg/c㎡ | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 |

| Air source flow | m³/min | ≥ 0.5 | ≥ 0.5 | ≥ 0.5 | ≥ 0.5 | ≥ 0.5 | ≥ 0.5 | ≥ 0.5 |

| Tool library form | / | Disc manipulator | ||||||

| Tool storage capacity | pcs | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Average tool change time (knife-knife) | sec | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Floor area (length × width × height) | mm | 5900×3100×3100 | 6900×3100×3100 | 7900×3100×3100 | 8900×3100×3100 | 9900×3100×3100 | 10200×3400×3200 | 12700×3400×3200 |

| Machine weight (about) | kg | 7000 | 8000 | 9000 | 9500 | 10000 | 10500 | 16000 |

Due to technical updates, product parameters are subject to change without prior notice.

A professional engineering technical support team, combined with the actual needs of customers and on-site conditions, provides one-to-one technical services and completes customized industry solutions.

Contact usTel

TOP